From 2D Design to 3D Sleeves

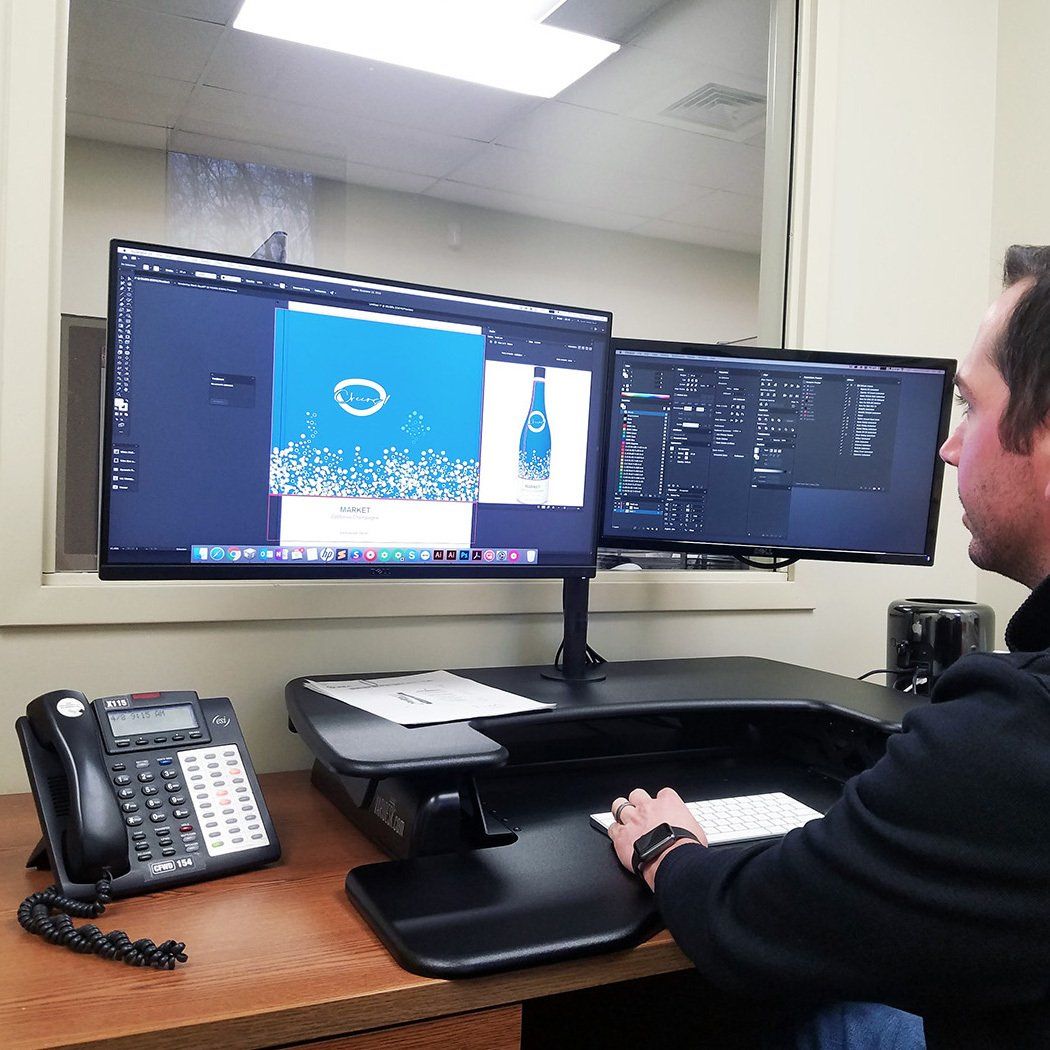

The Dion Label Printing prepress team always goes above and beyond to make sure the artwork you send us and your final packaging are aligned. With shrink sleeves, this is no different. Our team actively works with rendering software and their incredible design skills to make sure we get your packaging right. Because of the nature of shrink sleeves and the unique variety of the containers they can be applied to, the process our team uses for creating them is intensive and truly awesome!

The first step in the process is for you to provide us with a 3D file of your container (see

last week’s blog for more information on shrink sleeve design requirements). This is where the importance of the correct file types comes in. Our software enables us to map your shrink design correctly without all of those calculations done by hand, saving time and cost.

Once we have the 3D file and your artwork, we can begin working with our digital tools to bring them together. We map out the artwork to the 3D file of your container and our designers then distort it using special plugins and their wonderful design abilities. They actually simulate the physical shrinking process, just as the physical sleeve will shrink onto the actual container! And while the technology does many of the tough calculations, our prepress department carefully reviews every aspect of the design and adjusts as necessary. We even have the capabilities to create 3D snap shots of what the shrink sleeve will look like on the actual containers and make mini videos of the rendering for customers.

We are proud of the work our prepress team does to make 2D design come to life on 3D packaging.

Contact us today if you’d like to discover more about the incredible design work our team can do!

RECENT POSTS

WHO WE ARE

our solutions

our WORK

RESOURCES

DION LABEL PRINTING

FACILITY/MAILING

539 North Road

Westfield, MA 01085