Color Questions Answered: 4-Color Process, Extended Gamut, & Spot Colors

When you are designing your label, we know consistent brand color is one of your top concerns, but sometimes it can seem perplexing to communicate your color needs. Terms like 4-color process, extended gamut, and spot colors are often thrown around. Even if you understand the basic principles of the terms, perhaps you are still curious about exactly what they mean for your brand and your artwork. Our Dion team takes pride in our color matching ability, and we have the skills and expertise to get your colors right every time—which may be more important that you think, given that up to 90% of snap judgements made about products are based on color alone (https://graphicartsmag.com/articles/2017/03/expanded-colour-gamut/).

4-Color Process

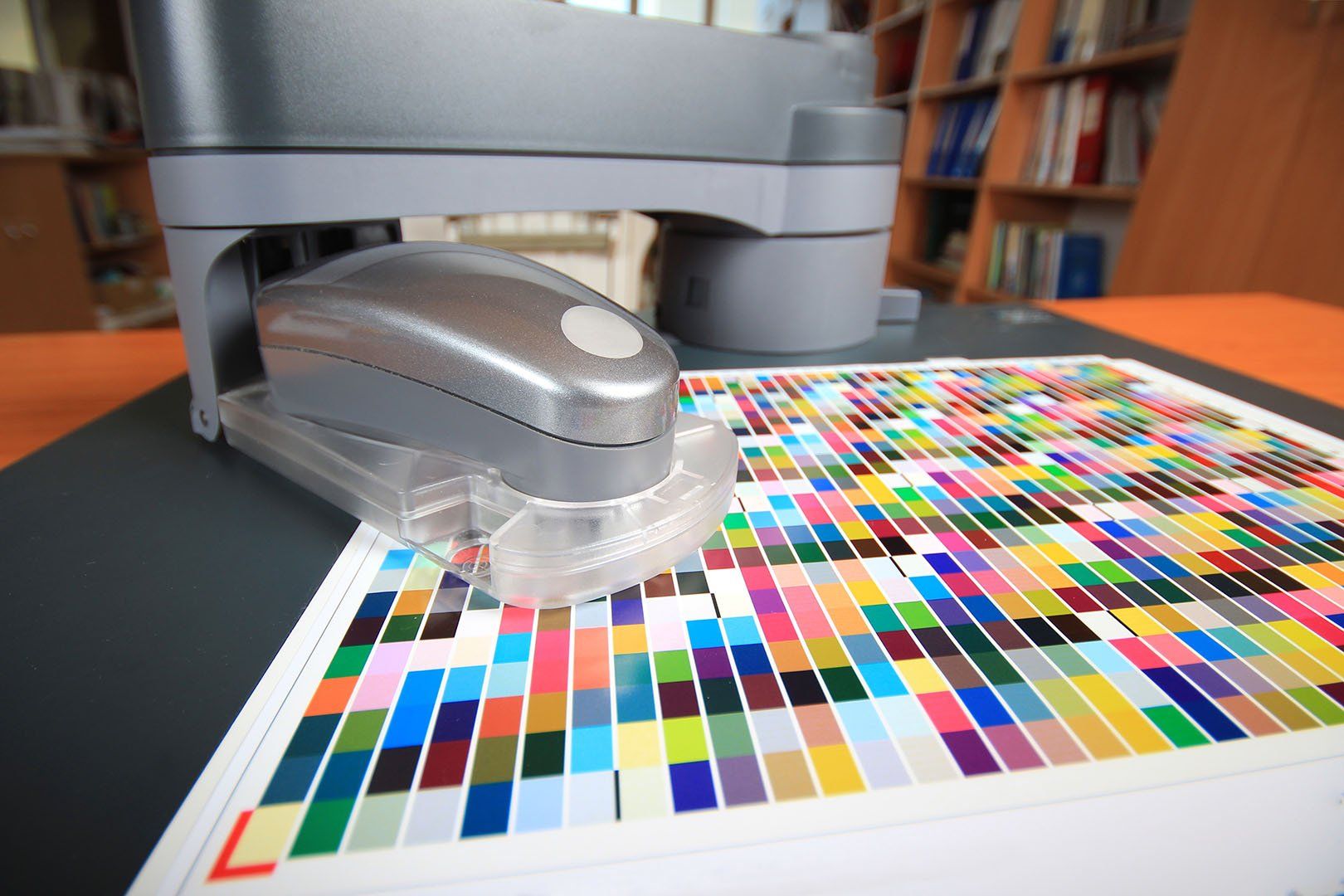

For digital printing, the ways to achieve color are through the 4-color process and the extended gamut. The 4-color process, or 4CP, is comprised of, you guessed it, 4 colors: cyan, magenta, yellow, and black (CMYK). These colors, mixed and printed in the appropriate amounts, can make a huge array of colors: 50% of Pantone colors in fact. The colors you see on a finished printed piece are actually made up of tiny dots of these colors combined in the right amounts. The quantity and variety of colors CMYK can produce is incredible; however, there are still colors that can’t quite be achieved with them. And while CMYK can come close to many colors, depending on how important color matching is to your brand, the 4-color process may not be able to match colors within an acceptable range for you. Dion will always review each piece of artwork to determine the right color values for quoting and determine if extended gamut is necessary. Plenty of times, CMYK will have you covered.

Extended Gamut

Printing using extended gamut process colors allows for a broader color gamut – CMYK plus orange, green and violet. By adding these three additional base inks into the process, you can achieve a much closer match to traditional formulated spot ink colors (explained below). For example, orange will look truer and cleaner when orange ink is used rather than mixing yellow and magenta to achieve a suitable match. HP Indigo’s superior liquid ElectroInk technology is the only digital color printing process that can match other traditional types of printing, delivering high resolution printing and perfect registration. Our HP digital presses allow us to meet strict brand color standards using up to 7 ink stations and a color gamut that reaches up to 97% of PANTONE® colors.

Spot Color

For traditional printing, spot colors are often used. The difference between spot colors and process colors is primarily in how the ink is applied during the printing process. For spot colors, the colors of your design are applied individually in layers, eventually filling in all areas of your design. Spot colors are blended prior to the printing process rather than during print. Spot colors can be incredibly custom; we use spot colors for many of our partners who require GMI printing like Target and Walgreens.

Brand consistency is integral to maintaining and growing a customer base for any company. Whether your label uses 4-color process colors, extended gamut, or spot colors, all of our presses have the capabilities to match your colors, and our technicians have the expertise to ensure that they are right, every time. All of our digital presses run on the same substrate definition files, so colors always match regardless what material you choose or what press your label is printed on. Our prepress team is meticulous in matching colors from art files to your final label product, and our technicians monitor your label through every step of the printing process, with the assistance of smart technology. If you are looking for a printer with the skills, knowledge, and equipment to make sure your colors are vibrant and on-brand for every label, look no further than Dion Label Printing.

RECENT POSTS

WHO WE ARE

our solutions

our WORK

RESOURCES

DION LABEL PRINTING

FACILITY/MAILING

539 North Road

Westfield, MA 01085