Stunning & Secure Labels with Cast and Cure™ Effects

As competition for consumer spending has increased for just about every consumer good, companies across the spectrum of industries are constantly on the lookout for new and interesting ways to differentiate their brands. Labels and packaging are one of the most high-impact ways for companies to attract attention and nudge buyers to their product over a plethora of others on the shelf. Dion Label Printing is a leader in offering a huge variety of specialty and high-decoration labeling options to our partners. From specialty and textured materials to foiling and selective gloss finishes, we have the solutions and skills to help set your products apart.

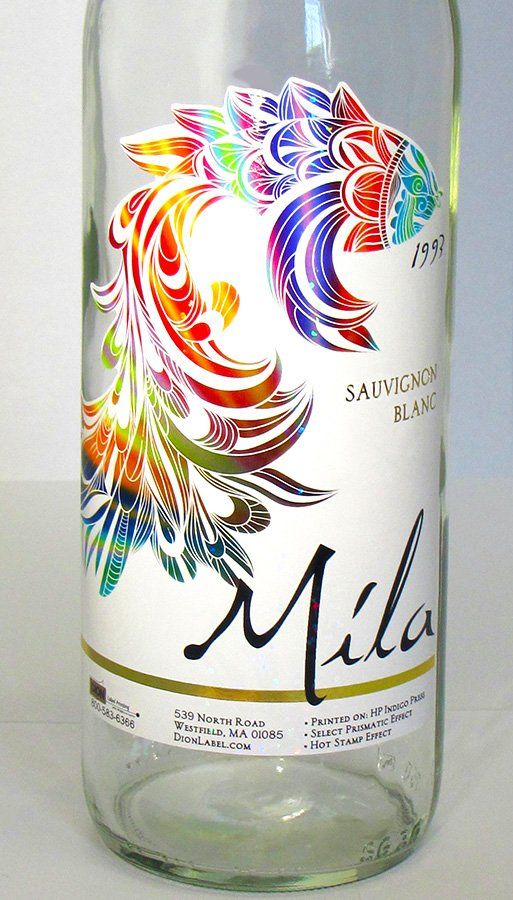

Cast and Cure™ is one of our amazing finishing options that will give your brand the edge it needs.

The Cast and Cure™ process begins with a UV coating applied directly to printed material. Cast and Cure™ film is then laminated to the wet surface. The film’s unique micro-embossed surface then imparts its pattern onto the coated surface. According to Label and Narrow Web, the origins of the Cast and Cure™ process are unclear, but it has been in use at least since the 1980s. Its applications since then have expanded significantly as companies increasingly look for ways to “attract consumer attention, create brand differentiation, protect their brands from a growing world of counterfeiters, or all of the above” (Label and Narrow Web). Not all printers have the ability to create a quality Cast and Cure™ label, but we at Dion guarantee the highest quality on all the labels we print, including those with special effects. If you’re looking for a way to make your label shine (literally) or you want some added security measures built right into your label, Cast and Cure™ may be just what you need.

Wormtown Brewery used Cast and Cure™ to highlight the celebratory essence of their 10th anniversary brew, Decade Dance.

Design

If you’re making consumer products, you are well aware of how fierce the competition is. Companies from all industries are increasingly searching for ways to differentiate their products and Cast and Cure™ offers a truly unique and flexible way to do so. The process, using UV coatings and specialty film, results in an amazing holographic appearance. There are many patterns available, from dots to stars. The design possibilities are endless, from a sparkling border around your artwork, to taking your logo to the next level, to a simple band of shine. The film can be applied all over the label for high visual impact or in smaller, more select areas as an accent to existing artwork. In fact, one of the greatest design benefits of the Cast and Cure™ process is its flexibility. The effect is applied only where the UV coating is printed, allowing for a wide range of design options from spot to flood coverage. We love the idea of using Cast and Cure™ treatment strategically to enhance certain design features.

Security

With the advent of e-commerce and the digital marketplace, companies in a variety of industries now have to be more wary of counterfeit products entering the market. Health and beauty, supplement, and pharmaceutical brands are just a few of the markets hit hardest by an influx of illegitimate products available for purchase. We offer a variety of security elements for your labels, including black light additives and microtext, but Cast and Cure™ is a unique security option because it is so visually appealing. As mentioned above, the film can be applied all over the label for high visual impact or in smaller, more select areas as an accent to existing artwork. The smaller the area, and the smaller the pattern, the harder it will be to detect.

It is much more difficult for counterfeiters to reproduce a label with the holographic effects created by Cast and Cure™, so if you’re looking to secure your product, this application may be just what you need.

Other Advantages

On top of the design and security benefits of a label with Cast and Cure™, there are some added bonuses. Unlike with other high decoration options such as foils, the film used during this process can be used multiple times, making this process less wasteful and more environmentally friendly. Plus, there are fewer recycling limitations with Cast and Cure™ films than with foils. What’s more, compared to other high-decoration and specialty labeling options, Cast and Cure™ is exceedingly cost effective. The process can be applied to almost any substrate that can be UV coated, so material choices are much less limited with this process than with some other high decoration options.

If you’re ready to get started on a labeling project with Cast and Cure™,

get in touch with us here. You can also

request a free sample packet and we’ll send you some amazing labels with high decoration effect like Cast and Cure™!

RECENT POSTS

WHO WE ARE

our solutions

our WORK

RESOURCES

DION LABEL PRINTING

FACILITY/MAILING

539 North Road

Westfield, MA 01085