Tamper Evident Shrink Sleeves

The safety of a product is something that many customers take for granted. For OTC pharmaceuticals and certain cosmetic items there are stringent FDA regulations requiring tamper-resistant packaging, but even in industries where there are not strict regulations, customers expect to see verification that the product they are buying is untarnished. If your company makes anything from lotion to food to supplements, however, you know that making sure your product is secure in its packaging is not always simple. Shrink sleeves provide an all-in-one label solution to questions of security, so you and your customers can rest assured that what they buy is safe.

There are numerous ways to provide tamper-evident packaging. You can use a secondary label, but that requires a second label application and added cost. You also need to determine the exact shape and size to make sure that it fits securely over the opening of your packaging. There are options such as “safety buttons” for jars of food items, but this means of tamper resistance can actually be reclosed with seals intact, although design has become more robust in recent years. Induction sealing, popular among OTC pharmaceutical companies, is yet another means of securing your packaging. This process, which applies aluminum foil seals inside the cap of a bottle, however, requires special equipment and can be fraught with issues. Delays in production time and overheating that can damage the seal layer are common problems, and induction seals are expensive, both in terms of time and financial output.

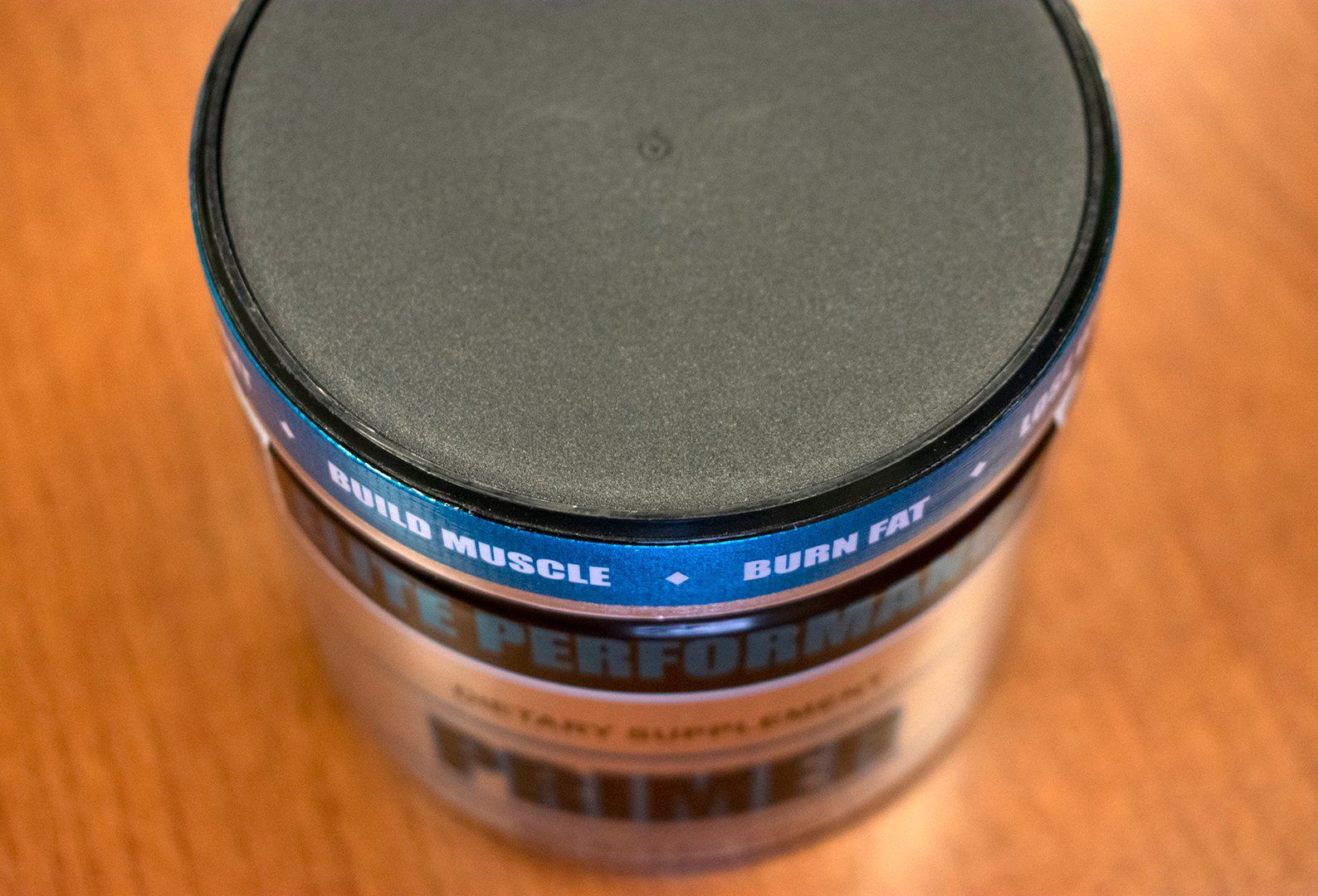

Shrink sleeves, on the other hand, offer all the benefits of security you want for your product without the hassle of other solutions. Because shrink sleeves can fit nearly any size and shaped container, you don’t have to worry about selecting standardized packaging that will work with other available methods of tamper-resistance. They are an economical option; in many industries, producing a safe item is the cost of entry, so finding a way to secure your product without breaking the bank is essential. Shrink sleeves are truly an all-in-one packaging solution. They can be shrunk over the entirety of your container and equipped with perforations, making access to a purchased product much easier once it’s been purchased. Customers know when they see an item that has a shrink sleeve that is has not been tampered with, and the added opportunity for design is just one more benefit of this incredible packaging solution.

If you want to assure your customers that your product is safe, if you’re concerned about the cost of securing your product, or if you are looking for a less complex method to provide security, shrink sleeves are the perfect option. You know that your product offerings are fantastic—let shrink sleeves communicate to everyone else that your awesome product is as unadulterated as the day it was produced! Read more about the range of benefits shrink sleeves printed by Dion can provide for your brand

here.

RECENT POSTS

WHO WE ARE

our solutions

our WORK

RESOURCES

DION LABEL PRINTING

FACILITY/MAILING

539 North Road

Westfield, MA 01085