Artwork and Printing Terms Defined – Dielines, Corner Radius, & More

There are a number of factors that come into play when you’re creating artwork that is going to print. Aside from making sure all of your design elements are on brand and appealing, there are many technical elements you also must ensure are correct. From setting up your files in the appropriate color format to establishing proper spacing, it is essential that you keep these factors in mind when creating your artwork. Here we’ll explain dielines, corner radius, bleed lines, and copy limit to help you on the way to your perfect label.

Dielines

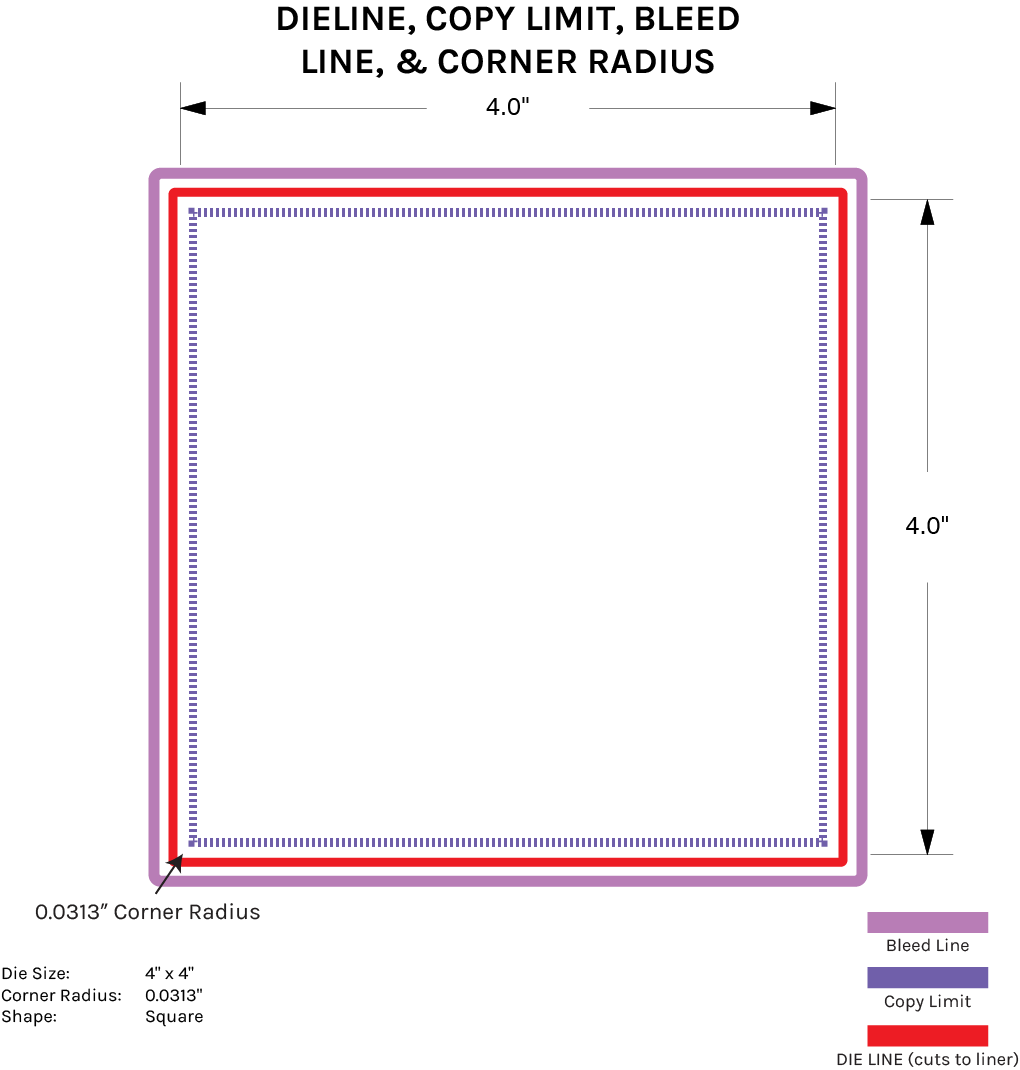

Whether your artwork is for a label or any other printed piece, your dieline is an integral feature. To put it simply, you can think of a dieline as the outline of where your printed piece will actually be cut. Obviously you will want to keep all of your artwork inside of the dieline, but you can also use it to help with alignment and spacing to ensure you have symmetry and appropriate layout for your artwork. Dielines are used in graphic design as placeholders to create proper layout of documents that will be diecut as part of the finishing process. Dielines should usually be placed into the design file as a separate layer for sizing and orientation purposes. A dieline is not printed on the final piece but is used to determine correct layout.

Corner Radius

The corner radius of your art is another important feature of your artwork, especially for labels. Corner radius describes how rounded the corners are on a rectangular or square diecut. A larger corner radius produces a more rounded corner, while a small corner radius produces a sharper corner that is closer to a squared corner. This measurement can affect both appearance and functionality, and it is important to keep in mind how it relates to your label application process. For machine application, corners that are too squared will make it more difficult for a label to release from its liner.

The above diagram shows how a template with dieline, copy limit, bleed line, and corner radius will look. Note: image is enlarge for reference purposes only.

Bleed Lines

We talked above about how your dieline will influence the appearance and layout of your artwork, and bleed lines play a role here as well. Bleed lines exceed past the limit of your dieline, and they are essential to help make sure there is not unintentional blank space on your final printed piece. Bleed lines are the boundary to which graphic elements, such as background images or colors, should extend to. The line itself extends beyond the edge of where the label will be diecut to ensure that no unprinted edges occur in the final product. If you’ve ever seen a printed work whose artwork did not extend to the bleed line and has blank space between the artwork and edge, you’ll know how unprofessional and shoddy it makes the entire piece look.

Copy Limit

Like a bleed line, a copy limit exists as insurance against unintentional differences between your digital art files and the final printed product. This barrier delimits the outer region in which you should place copy, or text, in your design. Its primary purpose is to ensure that all copy is legible on the final diecut product. Because your label is, in essence, a means to communicate with customers, having text that is cut off or illegible is unacceptable, which is why adhering to copy limits are indispensable when you’re creating artwork.

Dion Label Printing goes above and beyond to ensure superior quality on every label that we print. One of the first steps in our quality process is making sure your artwork files are set up correctly from the start. When you print with Dion, our prepress department is here to help make sure every aspect of your label meets our intense standards for quality and exceeds your expectations. Prepress is the term in the print world that describes our art department. This team plays an integral role in making sure all aspects of your label design are set up exactly right so that the label you envisioned is the label you receive. One of our artists will create a proof from your artwork which is then sent to our proofreaders. Our proofreaders’ jobs are to make sure that the proof can be read both by our production team and by you, the customer. They check every aspect of the proof, verifying that the technical information on the ticket, such as substrate material, copy position, die lines and corner radius, all match the proof. They can also create a custom dieline to suit your specific needs?

Contact us and we will help!

You can find more information and actual-size dieline templates for free download

here.

RECENT POSTS

WHO WE ARE

our solutions

our WORK

RESOURCES

DION LABEL PRINTING

FACILITY/MAILING

539 North Road

Westfield, MA 01085