Going Beyond with a High Decoration Shrink Sleeve

If you haven’t heard, more and more companies across a variety of industries are opting for shrink sleeves rather than traditional paper and film labels. Shrink sleeves maximize the amount of print surface space available for your brand. They can be shrunk to almost any size packaging, greatly extending your options for container size and shape. They also can provide tamper-evident packaging built right in. We’ve extolled the many virtues of shrink sleeves

elsewhere, but have you considered high decoration options for your shrink sleeve?

Metallic labels are one of the most versatile trends in label design, gaining in popularity across industries as varied as health and beauty products to food and beverage. Whether your brand is a nutraceutical hoping to stand out in an increasingly crowded field or an industrial product that wants to differentiate itself from the competition, metallic elements in your label design can help you achieve your brand goals. Incorporating metallic elements onto a shrink sleeve can be an incredible way to outshine the competition. We can print in metallic inks in various colors on shrink sleeves; if you’ve got metallic aspects to your label, we can make sure they are included if you decide to go for a high-impact shrink sleeve!

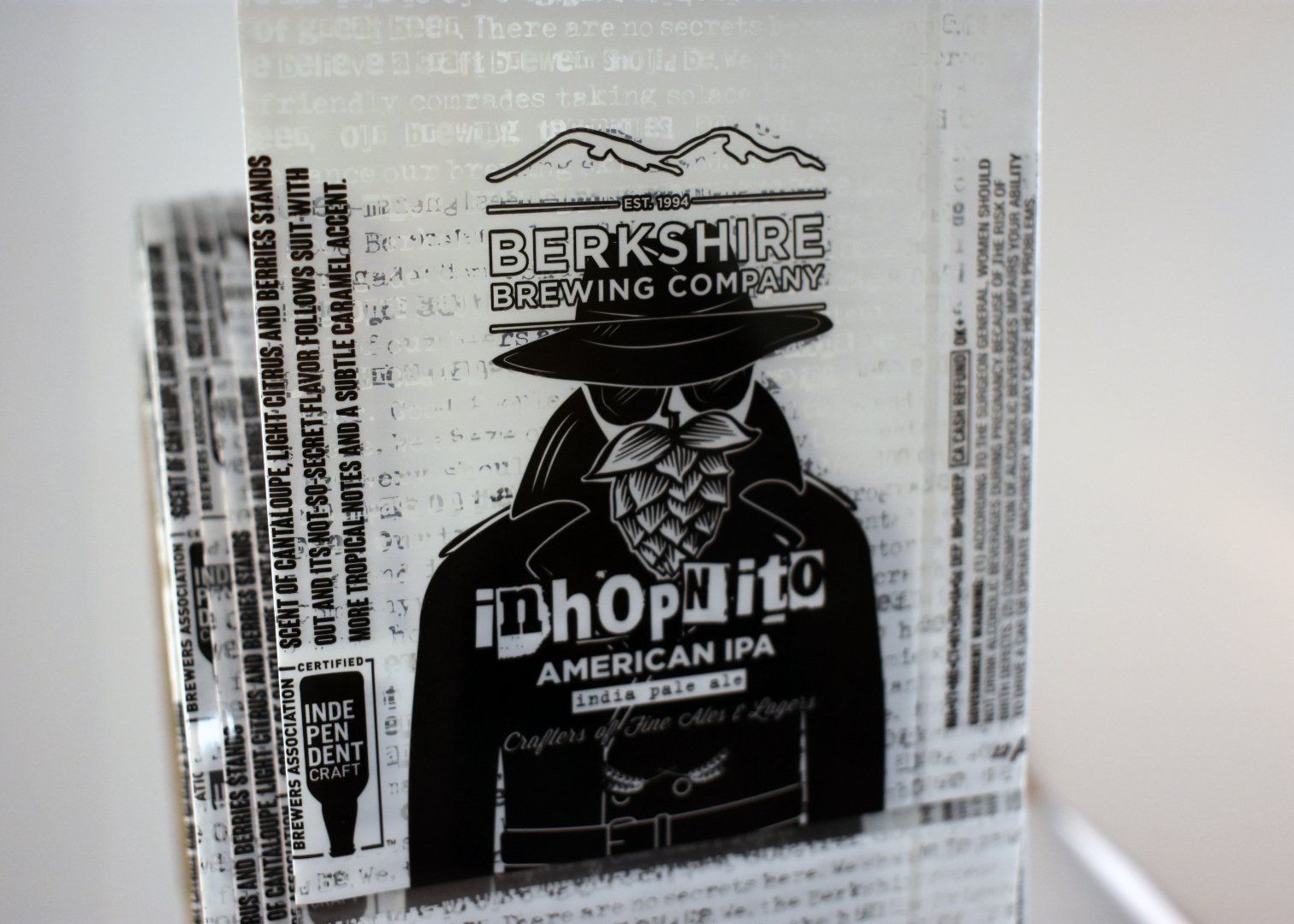

Another great way to incorporate metallic elements onto shrink is one that the craft beer industry uses often. If your container is already metallic, like the aluminum cans breweries often use to package their offerings, leaving unprinted space on a clear shrink sleeve lets the metal shine through (see

Berkshire Brewing Company's amazing InHOPnito shrink sleeves above). This can be an economical way to achieve the metallic look you are going for. Leaving unprinted design space on a shrink sleeve can also help you achieve a “no label look” that many standout brands are choosing.

If you desire an extremely luxe appearance, Dion can also include Cast and Cure™ and foil options in a variety of patterns and colors right onto shrink sleeves. Cast and Cure™ provides a holographic finish to specific areas of graphics or the entire surface area of your label. Cast and Cure™ on a shrink sleeve is a sure way to make sure your label has the impact you want it to. We can also use foil applications to create a dazzling effect on your shrink sleeve. Cold foil on a shrink sleeve enables you to use metallics in a way that exceeds the capabilities of metallic ink or packaging.

Why not

talk to a label specialist today to see what shrink sleeve solutions we can offer your brand? Or

request a free quote to get started on your next high-impact label project!

RECENT POSTS

WHO WE ARE

our solutions

our WORK

RESOURCES

DION LABEL PRINTING

FACILITY/MAILING

539 North Road

Westfield, MA 01085