Understanding Your Quote

We try to make the label ordering process as simple as possible for you (check out this video on the label ordering process here). To that end, here we’re going to break down our quoting process step by step in case you ever have any questions.

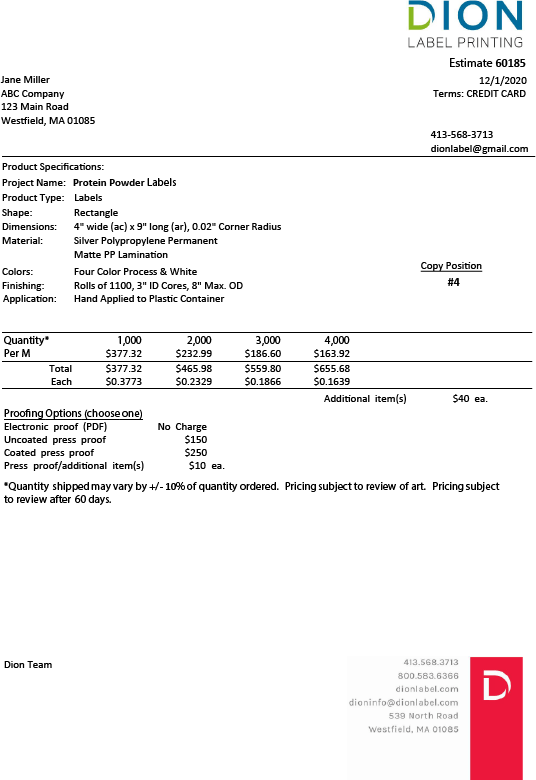

The first step in our quoting process is to fill out our request a quote form here on our website. Sometimes, if you’re working directly with a Label Solutions Specialist, they will also gather the information needed for a quote request from you personally. Once we have your quote request, we will reach out to you to confirm all the information on the request is correct and go over any questions you may have. 24-48 hours after receiving your request (and often much sooner), you can expect at email from our estimating team with your formal quote. It will look something like this:

You’ll see the top portion of your quote includes your company information, your estimate number, and your payment terms.

The next section of your quote is dedicated to your Product Specifications as determined by your quote request. Many of the categories are straightforward, but we will go through each section here to make sure you don’t feel any confusion or frustration when it comes to your quote.

Project Name: This will be determined based on your product type or specific print job and will be different for every new label order.

Product Type: We offer several different products including labels, shrink sleeves, tags, and more. Whichever category your order fits into will be listed here.

Shape: This one’s pretty self-explanatory! It’s the shape of your final printed product.

Dimensions: This is basically the size of your final printed product. The abbreviation (ac) stands for “across” and (ar) stands for “around.” While you likely are thinking of your label dimensions in terms of width x length, since we are printing on rolls we think in terms of across and around. You’ll also see “corner radius” here; this describes how rounded the corners are on a rectangular or square label. A larger corner radius produces a more rounded corner, while a small corner radius produces a sharper corner that is closer to a squared corner.

Material: You will likely have discussed material selection with you Label Solutions Specialist, but this section will include both your base material (ex. Silver Polypropylene) and your coating (ex. Matte PP Lamination). You will probably see the word “permanent” by your material; this refers to adhesive type. Most pressure sensitive labels use a permanent adhesive, but for some applications, adhesive type may be different.

Colors: Again, our team probably talked about color with you, so this section states what colors we will use to print your labels. If you want to learn more about color options like Four Color Process and Extended Gamut, we have a blog that answers all your color questions here.

Finishing: This section refers to how your labels will ultimately be shipped to you. It may include quantities per roll, as well as roll sizes. “ID Cores” refers to the inner diameter of the cardboard roll (core) that will hold your labels, while “OD” means outer diameter, meaning the entire size of your label roll with the labels on it (this size can be important depending on your application method).

Application: Will your labels ultimately be applied by machine or hand and to what material? Your application plays an important role in the label material that will be right for you, so this information is important.

Copy Position: You’ll notice this section is offset to the right on your quote. Copy position refers to the direction copy and artwork are printed on a roll of labels. Most equipment has a specified copy position. Check with your production team if your company is doing its own labeling. If you use a contract packager or private label manufacturer, reach out to them–they should have the specifications. You can learn more about copy position and download a helpful chart here.

Following the product specifications section, you’ll find an area dedicated to Quantities and Price. We will give you a breakdown of price for several different quantities, as our price tends to decrease as label quantity increases. Per M means “per 1,000 labels. You’ll notice an “Additional Items” charge; this is applicable to each additional SKU to account for artwork changeovers on press. You notice the asterisk after quantities calls out that final shipping quantities may vary by +/- 10% of quantity ordered, that pricing is subject to review of art, and that after 60 days the pricing is subject to review.

In the Proofing Options section, you will get to select which proofing method is right for you. All label orders come with an electronic (PDF) proof at no additional charge. For printed press proofs, you have two options. Uncoated press proofs will ship to you on the same material as your final label but will not have your lamination or varnish on them. Coated press proofs, on the other hand, will come on the exact material and coating (either lamination or varnish) as your final labels. There is a small extra charge for each addition item for printed press proofs.

And that’s your quote in a nutshell! Once you’ve received your quote, you can expect to hear from us within 24 hours to discuss the details with you. As usual, we are here if you have any additional questions. If you haven’t already, go ahead and request a free quote here to get started on your next label project!

RECENT POSTS

WHO WE ARE

our solutions

our WORK

RESOURCES

DION LABEL PRINTING

FACILITY/MAILING

539 North Road

Westfield, MA 01085